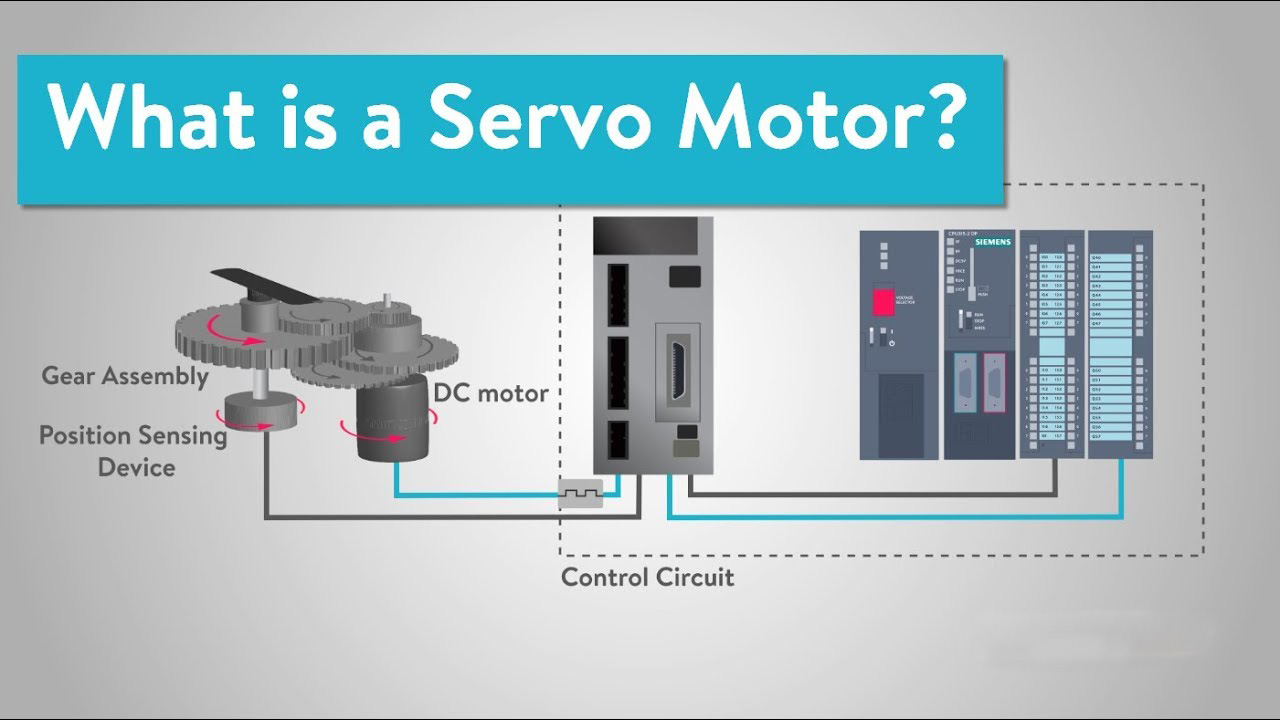

What’s a Servo Motor. Servo Motors are actuation devices for the precise control of speed, torque and position. A servo motor contains e feedback (encoder, resolver or a tachometer) which converts the mechanical motion (turns of the shaft) into digital pulses interpreted by a motion controller. It also contains a driver; and in conjunction, they make up a circuit that governs the position, torque and speed. Four components; motor, a drive, controller and feedback unit, comprise a servo system. Their main specifications are position, torque, velocity and acceleration.

Servo motors though usually quite small, pack a lot of power and efficiency which is why they are used in lot of industrial automation applications like robotics, metal cutting and forming, printing, woodworking, conveyor belt setups and more where high repetition yet precise work is necessary.

Types of Servo Motors

There are basically two types of servo motors - AC and DC. AC servo can handle higher current surges and tend to be used in industrial machinery. DC servos are not designed for high current surges and are usually better suited for smaller applications. Generally speaking, DC motors are less expensive than their AC counterparts. These are also servo motors that have been built specifically for continuous rotation, making it an easy way to get your robot moving.

Servo motors are used to power industrial equipment and machines where precision movement is of paramount consideration. But like any other machinery part, they can malfunction due to various reasons.

When servo motors fail and the machine goes down, it is frustrating and economically disastrous for the businesses. Inexperienced servo systems maintenance team and longer than usual repair turnaround times can lead to line operations being offline for hours/days or even for weeks.

It makes good economic sense to have backup motors and servo drives, should you need to ship a faulty servo motor for repairs.

In this troubleshooting guide we have put certain problems a servo motor can operationally experience which maintenance team technicians can identify and fix before contacting a repair establishment or shipping the repairable unit. This can save businesses time and money.

Common Malfunctioning and Prabable Causes: Servo Motors

Servo motors while in operation can experience the following issues and it may be possible for the plant technicians to look for these and apply desired fixes before contacting a repair establishment.

Overheating

Not only servo motors but all electric motors when in operation for an extended period of time, prone to overheating. The overheating is more pronounced during summer periods, it can occur during any season; even during extreme winters due to: -

Overuse - extended operating times

Increase of indoor and outdoor temperatures

Poor ventilation

Mechanical condition of company’s equipment. Older machines tend to overheat more often as their bearings wear our and friction increases.

An overheating servo can be catastrophic as the abnormally high heat levels can damage the equipment and ruin can spread to other parts of the connected system. A good servo will have a failsafe mechanism which will kick in and shut down the servo motor when the temperature goes beyond a dangerous threshold. But it doesn’t stop it from causing severe damage to connected equipment which will entail a shutdown and subsequent economic loss to the business.

So, what’s the solution? Preventive maintenance step one - Ensure your plant is climate-controlled and the temperature inside the plant is regulated well within operation limits. DO NOT try to cool the servo while it’s running by resorting to acts like opening the cabinet door or placing a fan close by. This will put extra mechanical stress and wear on the system. Excessive dust and dirt can and will kick in, damaging the electronics and mechanical components.

Timely and periodic mechanical service is a boon for older equipment which is prone to overheating. Replace most frequently moving older parts in older motors; bearings, seals etc.

Finally, always turn off an overheating system and let it cool off to a desired temperature over a period of time. If this frequently, where the equipment is idle more than its operational, you may want to consider replacing it.

Servo Motor Won’t Turn

This is another frequent issue, businesses face; the servo motor just doesn’t move. Since servo motor has many different components, its quite difficult to pinpoint the exact cause of this failure. However, one tip may help you shortlist this failure; check the servo controller’s Digital-Analog-Converter output. If you find a DAC parameter value of 0 or just shy of it, then that’s why the servo motor is not moving. There’s something wrong with the controller, and you may need to replace it. However, if the reading on Digital-Analog-Converter output is a large number, it means the controller is doing what it’s supposed to and the servo motor is having problems.

Again, if the problem is because of the drive, then try and run a self-test. This test forces the motor to operate at a low efficiency to observe whether or not it’s working properly. If nothing happens, then the problem is with the drive.

Abnormal Noises by the Servo Motor

A small amount of humming noise is natural by a normally operating servo motor and drive

Having that said, obnoxious, irritating loud noises are a cause for immediate concern. Incorrect wiring or electrical issues will result in a servo motor making strange noises. Shut of the power supply. Check for the grounding (Servo motor should be properly grounded) and make sure it’s getting the desired amount of power.

Reduced Torque

Torque comes from three basic sources: friction, external forces like fighting gravity and accelerating a mechanism’s inertia. Torque can be summed up as amount of muscle, energy or power required to rotate and move a mechanism.

Servo motors are built to put out a certain amount of torque so that if you choose the wrong one, it may not be able to handle the workload your team needs it to. Sometimes, you may also have a servo motor malfunction, and it will cease producing enough torque. Some of the most popular servos operate between 4.8v and 6.0v which is 130.5 oz-in and 152.8 oz-in respectively. Reduced magnets strength in stator or rotor is also one of the main reasons for reduced torque in servo motors.

If the servo motor is not delivering enough power, also check the following:

- Servo amplifier rating.

- Workload limits of the Servo

- System voltage drops or low voltage

- Weak or bad capacitors.

- Loose or improper connections.

With experience maintenance team technicians become familiar with how to test servo motor and drive systems because this happen quite often, especially with older and legacy equipment.

Servo Motor Produces Odor or Produces Smoke

More than likely, if your servo produces a burning smell; it’s clear indication that your system is overheating. Check cooling system and air flow to ensure it’s unobstructed. Check to see if the bearings are smoothly operating. There can be many issues including too much lubricant, worn bearings and overheating. Encounter ozone like smell indicates burning windings or wiring. If that’s the case, need to ensure the wires are contactless and the system is grounded properly.

Servo Motor Shuts Off Upon Attaining Full Speed

Servo motor shut off after it starts fine and after attaining peak speed is a sign of serious malfunction. This problem may be a little harder to repair at the plant level. Few factors may cause the servo motor to shut off, namely:

- Rapid overheating

- Worn out or improper bearings.

- Defective overload protection system.

- Blown fuses or fuses in need of replacement.

- Weak or bad capacitors.

- RPM meter malfunction or inaccurate readings.

- Poor wiring resulting in Voltage drops

The Servo Motor, at this stage, most likely, needs repairs by a professional to fix it.

How to Repair Servo Motor Components: Fixing the Problem

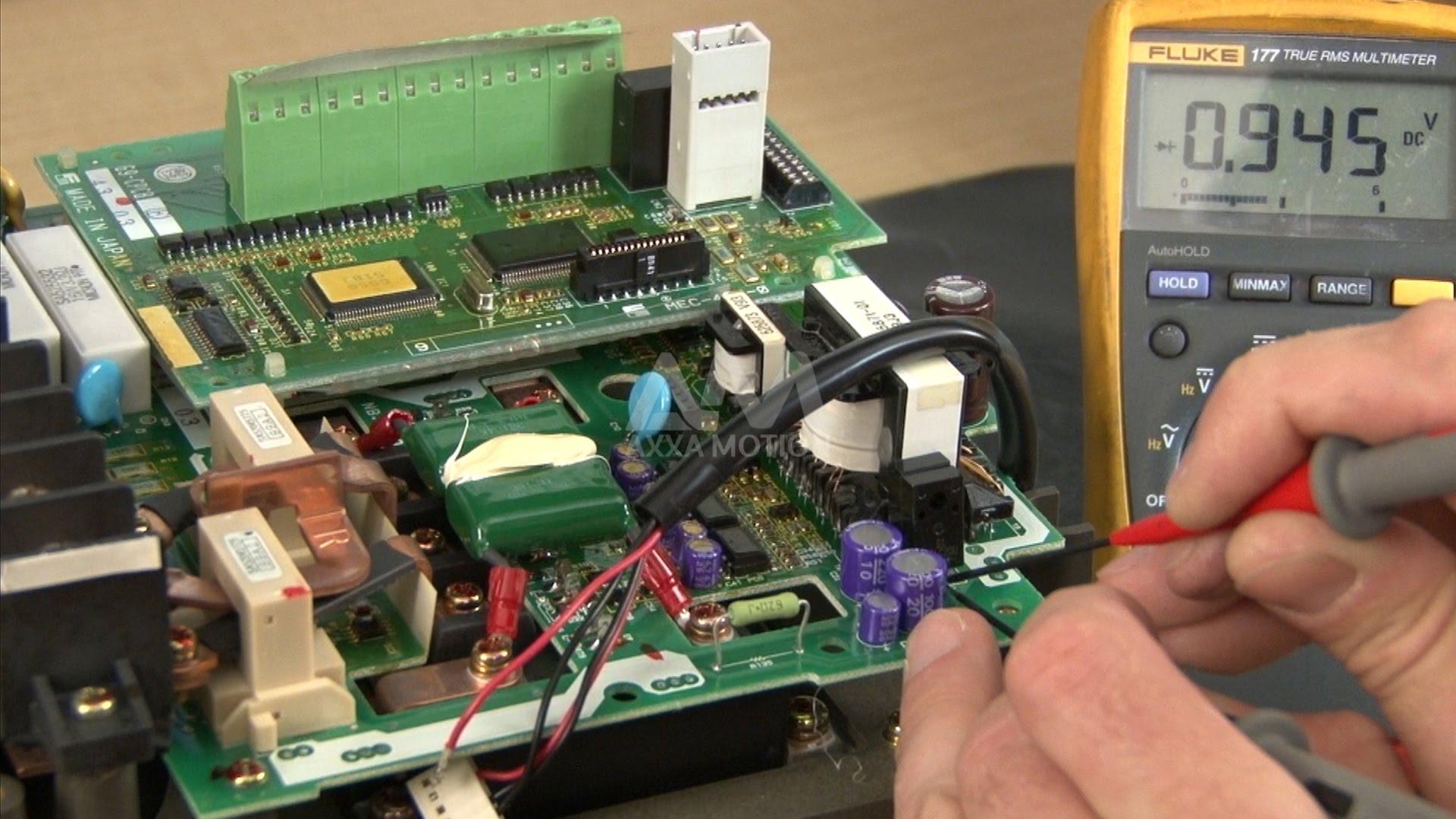

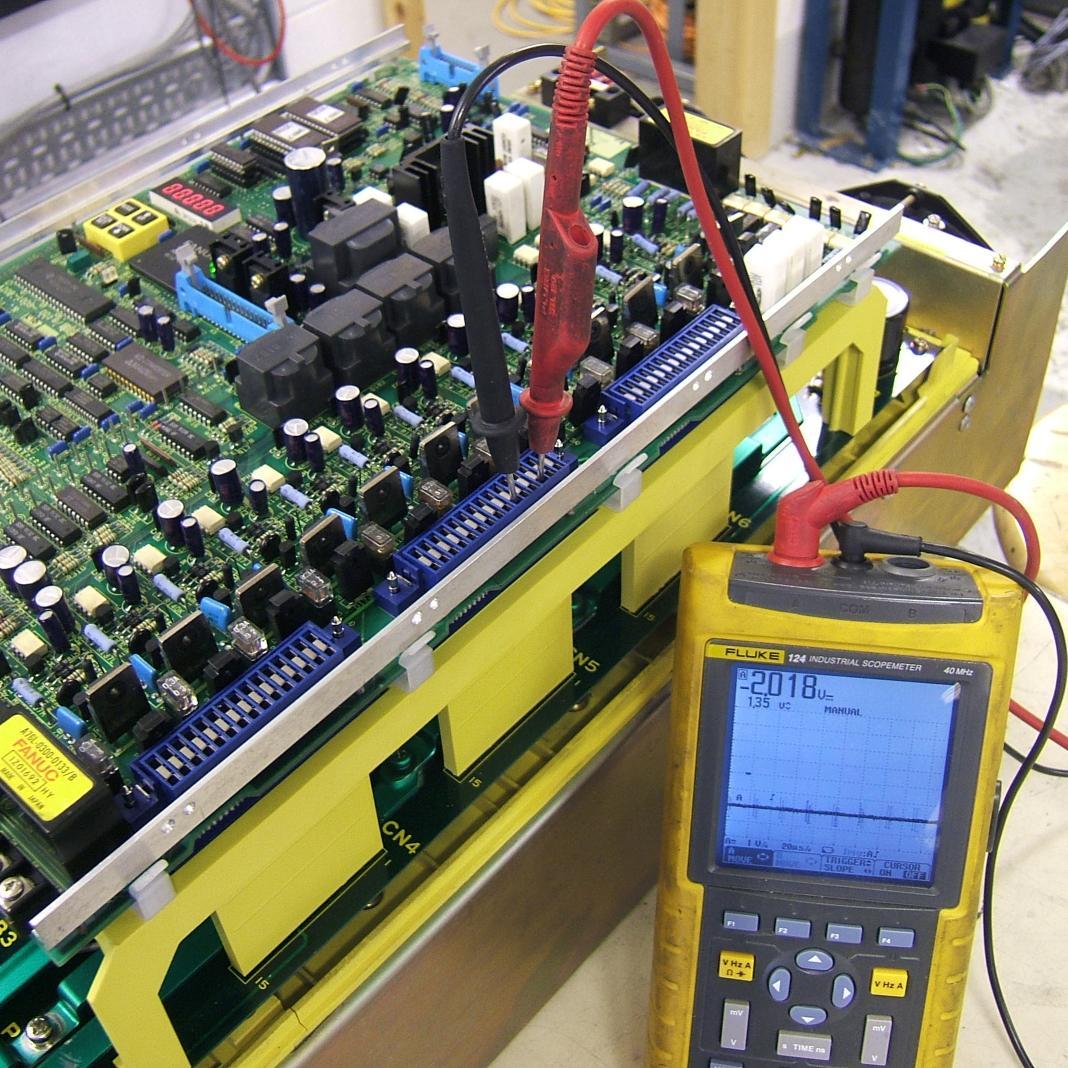

Once plant maintenance team technician has shortlisted the problem, the next logical step is to get the Servo motor/Servo Drive/ Amplifier/Controller repaired. Make sure you have the appropriate testing tools and meters before moving on to the next section. A word of caution, servo equipment is complex and every repair organisation may not have access to the specialized tools and gadgets to diagnose and fix the servo motor/ servo drive.

Troubleshooting and Repairing

Servo drive troubleshooting and servo motor troubleshooting are the backbone of identifying and fixing a problem. The ultimate goal is to work with and sometimes operate the servo to deduce what’s going wrong. Luckily, most servo drive and motor systems are attached to an alarm which will sound when something is up.

WARNING: Troubleshooting a servo drive can be a complex and dangerous process. It requires working knowledge of electromechanically controlled motors, actuators and a volt-ohm meter. If any of these components seem foreign to you or your team, outsource help. While reading up on how to repair servo motor and drive system, you’ll want to be prepared before taking action.

Your servo may be slightly different than what is being explained here, yet the following troubleshooting steps should remain the same:

- Switch off power to the unit, inspect the MOSFETs, inputs and outputs, IGBT’s relays, feedback circuits, power supplies and capacitors.

- Turn on the power to the machine and check the LED or readout display. If there is a screen and it does not come on, make sure there is power supply. If the alarm comes on immediately before anything else powers on, then your problem is probably the servo drive. If the drive begins working before the alarm sounds, you can rule it out.

- Inspect the servo drive and motor to identify broken, missing or bent parts.

- Check the motor and cable plugs. If you notice any irregularities, you may need to replace these components.

- Review the diagnostic or lead meters to see if there’s unnecessary friction in the motor axis. Friction is a rare problem, but it can happen and usually does when there’s too little — or too much — lube.

- Inspect the motor box coolant or air flow system. Make sure to clean or remove particles, dry out any plugs and check all cables.

- Check for a bind in the axis or if the brushes are worn down in the DC motor.

- Use a volt ohm meter to check for an incoming power supply. You’ll mainly want to test the servo drive to ensure the voltage is correct.

Of course, your maintenance team may run through all these steps and still have trouble identifying what’s wrong. That’s okay.

Look at these questions and see if they fit the problem your equipment is having:

- Does the alarm sound, or does the motor have problems in feed or during rapid movement? There may be a bind.

- Is there a loud hum coming from the servo motor? Your motor axis likely has a bind.

- Is there a loud growl or similar noise during high-speed operation? The bearings are bad.

- Does the motor slow down or stops abruptly? You might have an electrical problem. Check to make sure that coolant didn’t seep into the electrical box or one of the axes.

Once you complete a repair or replacement of parts, you’ll want to test the servo motor before putting it back into regular operation. You can do this by plugging it into a universal tester, which will provide information on the feedback, phases, rotation, speeds and direction under load. Also, don’t subject it to a heavy workload right away. Ease it back into operation by starting slow, just to ensure everything is in proper working order.

Need Help After Troubleshooting?

Should you not be able to getting the servo up and running again even after all the bone breaking troubleshooting and upkeep regimen, your maintenance team may not want to admit that they need help. It’s perfectly normal in such a situation. However, we can assure you that using a reliable servicing company like Axxa will help bring your servo back in operation in least time, and it will be economical to do it. Axxa technicians follow a laid down procedure from inspecting the motor to performing necessary tests and fixes and painting the station. We, at Axxa, adhere to a quality control regimen and audit the components to ensure that everything is functional and reliable.

We assure you that our servo motor repair and servo drive repair practices are reliable, economical and meet or exceed OEM standards. Give us an opportunity to be your partner in progress. Contact Us or Call us at (716) 270-0047 today!